Super-sized Injection Molding

Make the impossible possible!

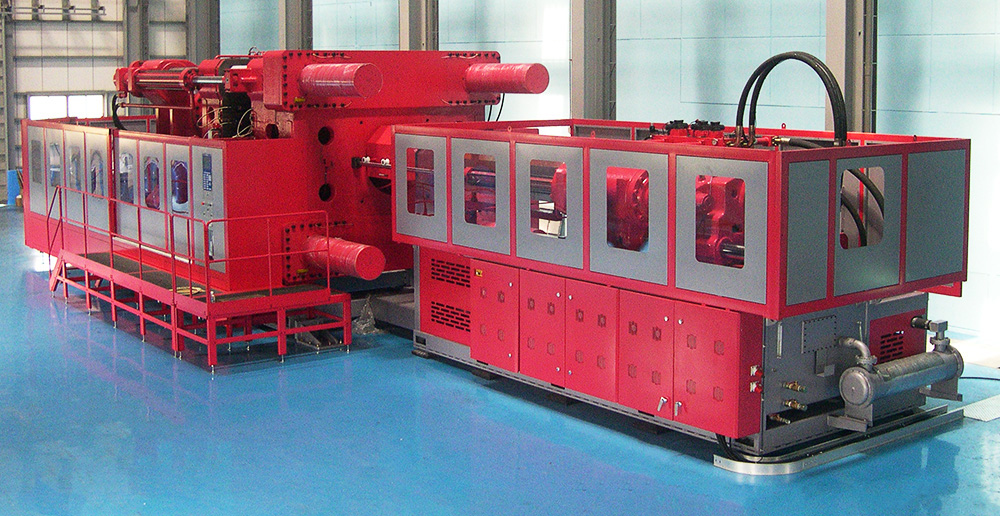

Super-sized injection molding machine was introduced.

A 4000-ton injection molding machine in our factory is one of the largest in Southeast Asia. It can mold a product of 25 kg at maximum. It enables molding of a part that has been considered impossible to produce integrally with resin. The light weight of the resin reduced costs and integral molding expanded the design possibility. It means that we can respond to various requests from customers and reduce preparation time and molding cycle time, reducing costs by improved production efficiency. Automotive bumpers, tractor fenders, and hoppers that contain fertilizer to be spread are the main products.

Product Examples

Hopper

This technology shifted the production method of large resin product from hand lay-up (FRP) to injection molding, reducing the number of man-hours and material costs.

Tractor Fender

A large part that was separated in the past is now molded integrally.

Instrument Board

We could integrate the product with a complex shape in order to lower the cost and improve durability.